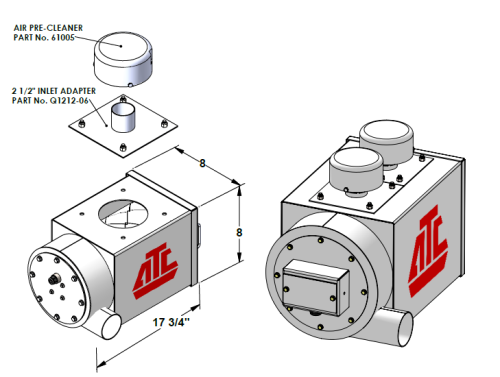

This air filtration solution is designed and manufactured by Arctic Traveler Canada to withstand the harshest mining and off-road environments. The pressurizer is a compact unit made of heavy-gauge welded steel with a powder-coated finish that is easy to install and requires minimal space. The pressurizer housing is made of heavy-gauge welded steel with a powder-coated finish capable of withstanding the harsh conditions of off-road equipment.

Innovative in all aspects of filtration, ATC designs air purification systems that continuously protect operators.

Cabin air quality is essential to providing a healthy and productive work environment. Whether in agriculture, construction, mining, or waste management, operators spend a large portion of their time in the cab of their equipment.

Both Air Filtration Solutions (60 & 100) include a pressurizer housing, a pre-filter and a three-stage filter element, tested by independent laboratories certifying HEPA efficiency (99.97% at 0.3 microns), according to the IEST (Institute of Environmental Sciences and Technology) test protocol – www.iest.org.

View Specs for both Air Filtration Solutions below

Air Filtration 60 Filter specification (60)

Air Filtration 100 Filter specification (100)

Pressurizer Selection Guide

Pre-Cleaner

Before outside air reaches the filter elements, it passes through the efficient, maintenance-free, stainless steel Enginaire pre-cleaner. This pre-cleaner removes up to 97% of debris before the air reaches the filter element. Its robust design allows it to handle all types of debris.

See how the Enginaire pre-cleaner performs compared to the competition.

Discover the power of the Enginaire pre-cleaner, which can crush rocks .

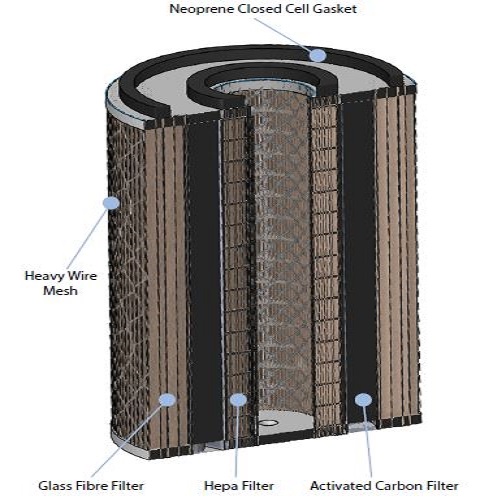

Three-Stage Filter Element

All filter elements are 100% leak tested to ensure there are no defects that would allow unfiltered air to bypass the filter media. Each filter element is traceable and bears a label with a unique serial number.

Filter Element – Stage 1: Fiberglass Filter – Moisture Resistant Protection

The Stage 1 filter element uses reliable, moisture-resistant filter media made from finely pleated glass nanofibers, which will not be damaged if moisture enters the system.

This first stage captures larger particles not removed by the pre-cleaner.

The design maximizes the surface area of the filter media, allowing for increased particle holding capacity and lower pressure loss.

Stage 2: Activated Carbon Filter – Superior Fumes Absorption

ATC has increased the activated carbon content in the Stage 2 filter element, achieving a superior absorption profile for organic vapors and fumes.

Filter Element – Stage 3: HEPA Filter – High Particle Filtration

HEPA-rated fiberglass filter media provides the ultimate level of filtration, achieving 99.97% HEPA efficiency at 0.3 microns.

A differential pressure gauge or electronic pressure monitoring system is available to measure the pressure difference between the inside and outside of the cabin.

These technical products, designed for intensive HVAC applications, are specially developed to meet stringent requirements, ensuring durability, robust performance, and consistent reliability.

From concept and design—using three-dimensional images created in SolidWorks—to manufacturing and delivery, all products are designed to precise specifications.

Serving commercial and industrial sectors such as agriculture, construction, forestry, mining and emergency services, our solutions are specifically developed for OEMs, tailored to the aftermarket, and designed to deliver reliable service in extreme conditions.

To view more of our engineered solutions, click here or for more info call 1-888-359-3366